3D puff embroidery is a unique and creative way to decorate clothing, accessories, and other textiles with a raised, three-dimensional design. The process involves using unique foam material, thread, and needle to create a raised design that stands out from the garment’s surface or fabric. The result is an eye-catching and visually appealing embellishment that can take any garment from basic to stylish and personalized.

The history of 3D puff embroidery can be traced back to the late 1980s, when it was first introduced to add dimension and texture to logos and designs on athletic wear. Since then, it has evolved and expanded to include various applications, from high-end fashion to custom-made hats and bags. Today, 3D puff embroidery is a popular choice for personal and commercial projects, offering endless possibilities for customization and self-expression.

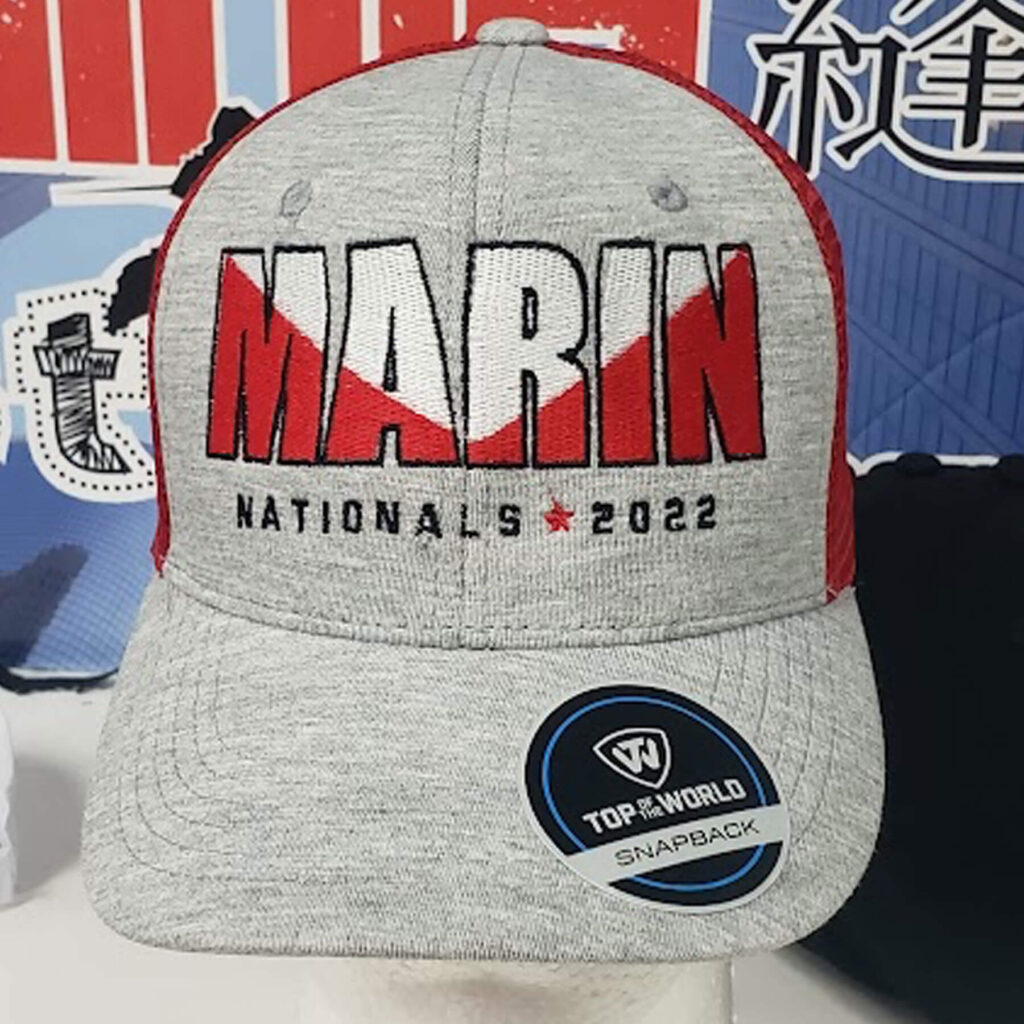

One of the key benefits of 3D puff embroidery is its versatility. Unlike traditional embroidery, which is typically flat and lays on top of the fabric, 3D puff embroidery can be used to create a raised design that stands out in three dimensions. This means that designers and artists have the ability to add depth and texture to their designs, making them more interesting and visually appealing. In addition, 3D puff embroidery can be combined with other techniques, such as printing or applique, to create multi-layered, intricate designs that truly stand out.

Another benefit of 3D puff embroidery is its durability. Unlike screen printing or heat transfers, which can crack, fade, or peel over time, 3D puff embroidery is made to last. The foam material used in the process is strong and durable, and the threads used to stitch the design in place are resistant to fading and wear. This means that 3D puff embroidery designs can hold up over time, even with frequent washing and wear.

3D puff embroidery is also a great choice for those looking to add a personal touch to their garments or accessories. Whether it’s a custom logo, a monogram, or a unique design, 3D puff embroidery allows for a wide range of customization options. Designers and artists can choose from a variety of colors, fonts, and styles to create a design that is truly one-of-a-kind. This level of customization is not possible with other forms of embellishment, making 3D puff embroidery a popular choice for those looking to make a statement with their clothing or accessories.

The process of creating a 3D puff embroidery design involves several steps, including preparing the design, digitizing the design, hooping the garment or fabric, and then actually stitching the design. The first step involves creating a design or choosing an existing one. The design can be created by hand, using graphic design software, or by using an existing pattern or template.

Once the design has been created, it must be digitized for embroidery. Digitizing is the process of converting a graphic design into a stitch file that can be read by an embroidery machine. This step involves defining the stitch type, stitch direction, stitch length, and stitch density for each part of the design.

After the design has been digitized, it must be hooped or placed into an embroidery hoop. The hoop is used to keep the garment or fabric taut while the design is being stitched. This step is important to ensure that the design is stitched evenly and without any puckers or folds.